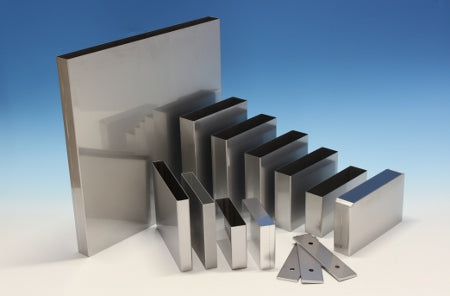

Welded Structure Battery Cases

Low Cost, Short Delivery Time

Proven Performance, Advanced Technology

Case Study

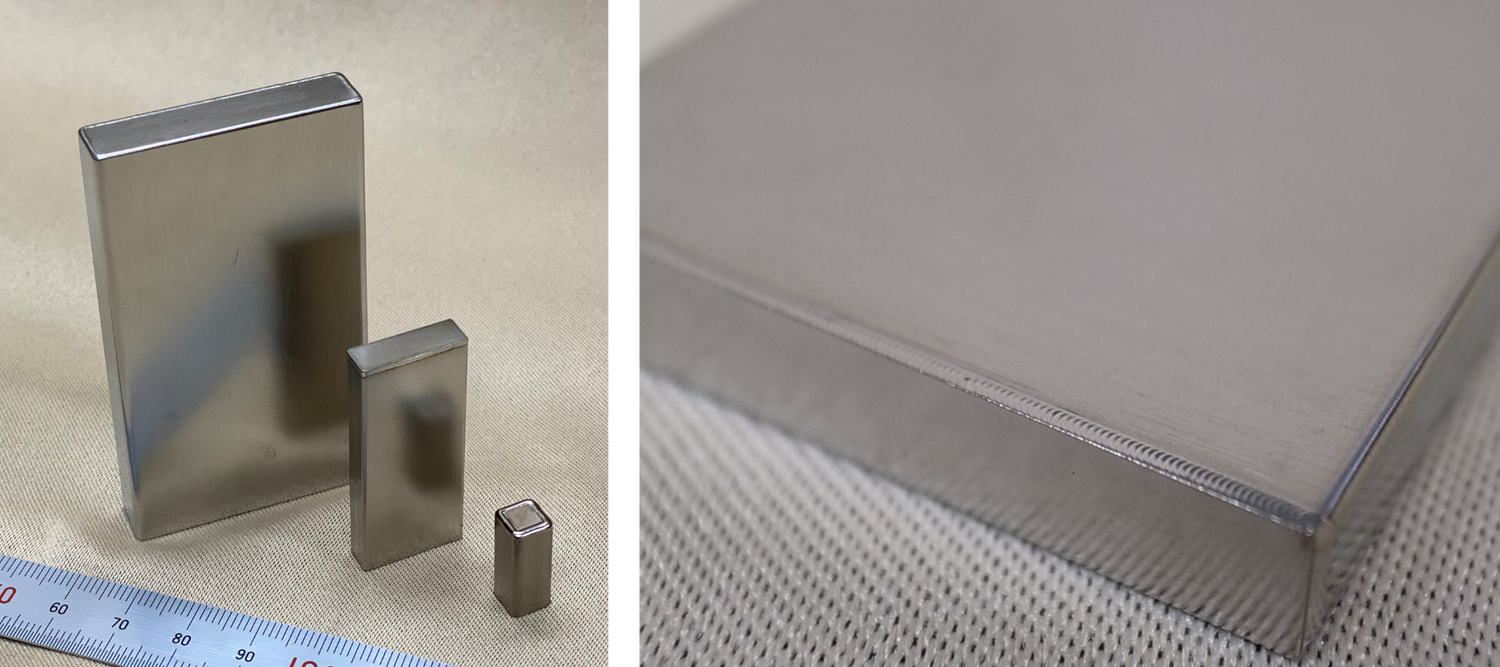

Titanium Alloy (Ti-6AL-4V) Battery Case

While Ti-6Al-4V alloy has excellent mechanical strength, it is challenging to draw deep and extremely difficult to weld. Our technology enables sound welding, making it possible to produce the battery case shown in the following photo.

Quality Assurance

JIS Q 9100 Certified

Our Shimamoto Factory was certified in September 2015 for JIS Q 9100. This means it meets the requirements for quality management systems in manufacturing specialized battery parts for civil aircraft and space applications.

Production & Quality Control Systems

We take a centralized approach to production and quality control. From receiving an order to delivering the product, every stage is managed through an integrated database. Our manufacturing records ensure that our products are all traceable.

We will help you choose the best product for your needs.

Available in both English and Japanese.

Our professional staff will provide you with detailed customer service.