Why Ohkita

Our Product First Approach

For over 40 years, we’ve put our heart and soul into the art of manufacturing. There has been more than just quality, price, delivery, and service to our success: we believe that the many opportunities we have had to develop products together with customers have resulted from our dedication and pride in manufacturing products with sincerity.

We continue to forge ahead with the firm belief that our worldwide customers can share and respect our philosophy on manufacturing.

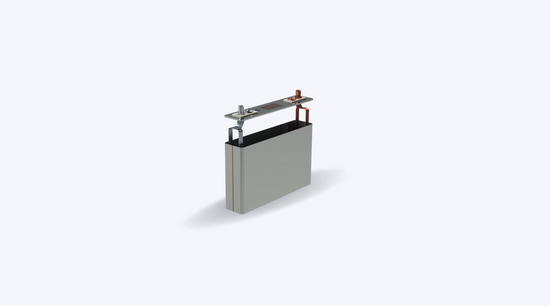

POINT-01We Welcome High-Mix, Low-Volume Orders

Our goal is to minimize the risk of new installations of specialty batteries for our customers.

We have over 40 years of experience with these products and have delivered to aerospace and automotive manufacturers and small-volume production for many customers.

Our dedicated team knows the budget, machining accuracy, and on-time delivery risks. We can help you develop and produce specialized products.

POINT-02Our Cost & Speed Advantages

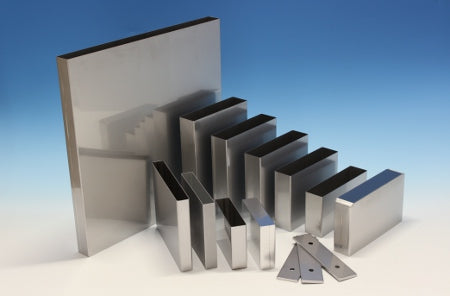

We manufacture cases with bending and welding techniques, eliminating the time and expense associated with deep-drawing dies.

We can rapidly produce and ship orders ranging from small lots to mass production.

The total cost can be reduced by up to 90% by manufacturing cases without drawing dies.

There are no depth limitations.

POINT-03We Can Handle Technically Demanding Processing

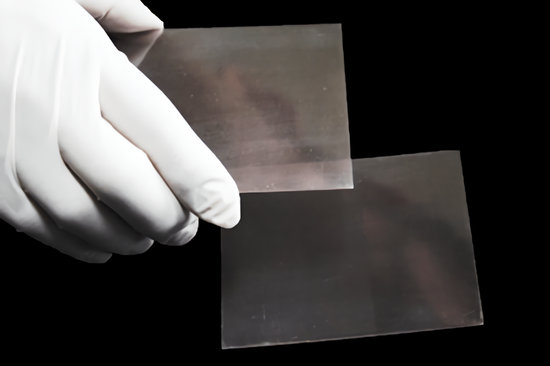

In addition to specializing in the manufacture of welded cases, we also have expertise in laser welding, pressing, machining, water-jetting, and insulation coating because welding technology alone is not enough to meet our customers’ needs.

As a higher-level technology than other companies, we can handle laser welding, which is a difficult task. We have over 25 years of experience in laser welding as an off-line job store.

We are constantly expanding our capabilities. For example, we have recently begun handling new specialized applications with insulating electrodeposition coating, which provides high insulation to metal components with a uniform thin film of 40 µm.

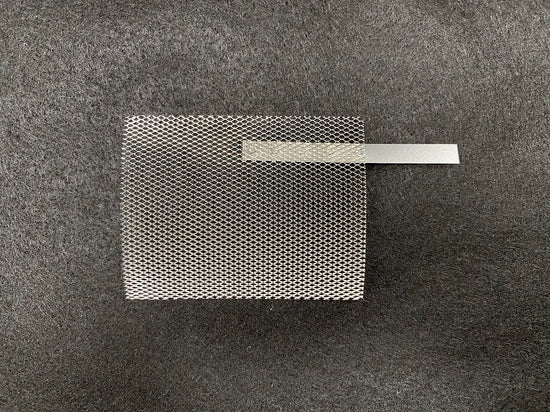

POINT-04Your One-Stop Shop for Specialized Battery Components

With over 40 years of experience in manufacturing special-purpose battery components, we can make proposals one step ahead of our customers’ requirements. You can use our products with peace of mind.

As a one-stop-shop for various methods, we have many in-house processes to produce specialized battery components. We provide high-quality products by giving meticulous support for complex processes.

POINT-05JIS Q 9100 Compliant Quality Control

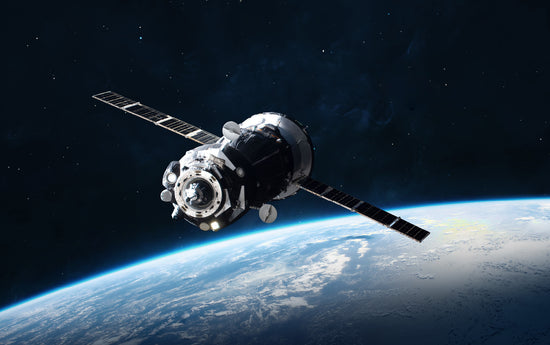

Our Shimamoto Factory has acquired JIS Q 9100 (≒AS9100) certification for “the manufacture of special battery components for commercial aircraft and space.” In other words, the plant is officially recognized as being equipped with the quality assurance systems required by the aerospace industry.

We will help you choose the best manufacturing process for your needs.

Available in both English and Japanese.

Our professional staff will provide you with detailed customer service.

- Choosing a selection results in a full page refresh.