Quality Assurance

Our JIS Q 9100 certification:

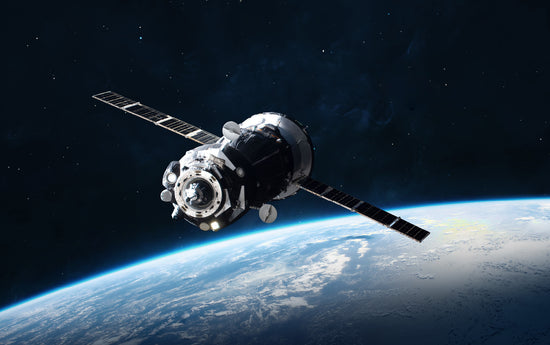

Our Shimamoto Factory acquired JIS Q 9100 certification in September 2015 for “manufacturing special battery components for commercial aircraft and space.”

About JIS Q 9100 :

JIS Q 9100 is a Japanese system management standard. It is technically equivalent to AS 9100 in the US and EN 9100 in Europe, based on ISO 9001 with additional requirements specific to the aerospace and defense industry.

Our Quality Inspection Department

Since we handle a wide variety of products produced in small quantities, we have established an inspection department separate from our manufacturing operations to perform various inspections efficiently.

We perform the following inspections in response to customer requests. Many of our customers have placed their trust in our quality.

Quality Inspection Items

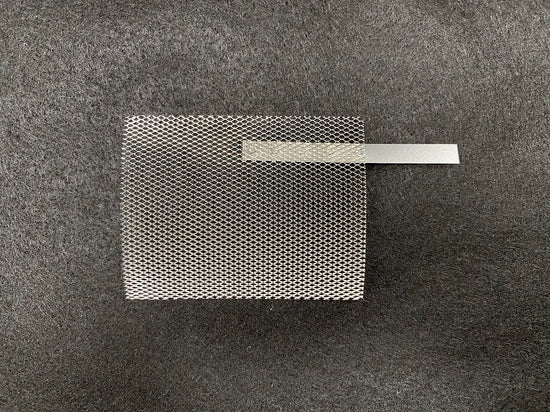

Appearance Inspections

Our appearance inspections are highly accurate to meet even the strict appearance requirements (scratches, etc.) of space applications. We visually inspect products for defects.

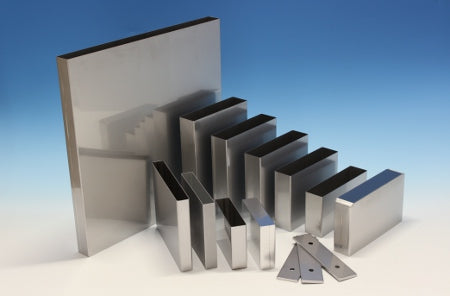

Dimensional Inspections

We inspect whether each dimension is within the required tolerance by using measuring instruments suitable for each application such as calipers, micrometers, height gauges, image measuring instruments, three-dimensional measuring instruments.

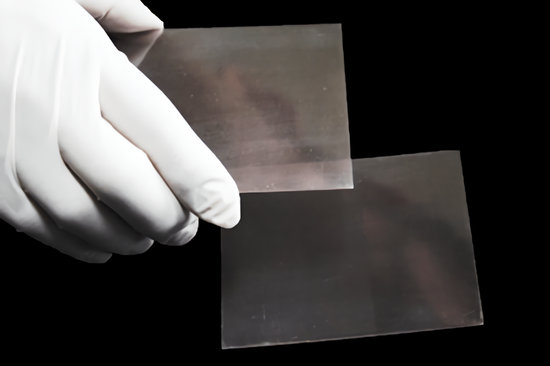

Helium Leak Tests

In this type of leak testing, helium is used as a tracer gas and its leakage measured. This enables us to detect leakage in products that require airtightness and detect defects that are invisible to the human eye.

Penetration Tests

Apart from using Helium leak test to test airtightness, we can also perform penetration testing of weld quality for products that require such testing.

Tensile Tests

We use tensile testing machines to check the mechanical properties of materials and ensure the quality of our welding as well as for various other purposes.

Hardness Tests

We utilize Vickers hardness testers upon customer request and to control the hardness of current collectors, measure the heat-affected zone of welds, and various other purposes.

Our Quality Management Systems

Our products are of high quality and reliability and are used in deep-sea research vessels, the International Space Station, and other aerospace-related components.

Aerospace-related products require traceability management to address defects and investigate their causes promptly.

We have established reliable production, quality control, and information management systems to ensure the timely delivery of high-quality products. We respond to customer requests and consultations for any type of management processes required.

Our Approach to Traceability Management

Traceability management is the process of recording materials and manufacturing conditions by lot number so that the manufacturing history can be traced.

To ensure that this mark is, above all, a trust for safety and security, we have established a reliable quality control system to deliver high-quality products. You can rest assured that we only deliver our products after checking them thoroughly to meet the required specifications.

We will help you choose the best manufacturing process for your needs.

Available in both English and Japanese.

Our professional staff will provide you with detailed customer service.