Lithium-Ion Secondary Battery Prototypes Components

We have been manufacturing lithium-ion secondary battery prototype components for over 20 years and have been working with at least two customers every month for the past five years. Despite often challenging some parts and processing techniques that are unprecedented in the world, we have an exceptionally high customer satisfaction rate.

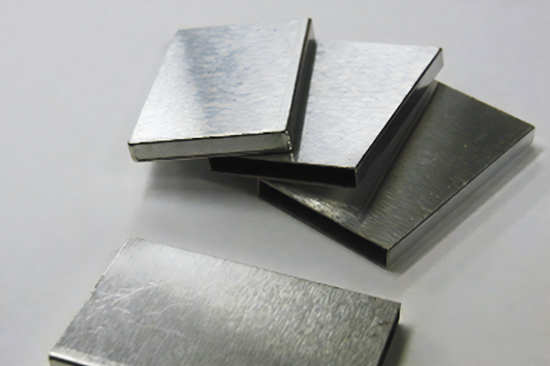

Cases

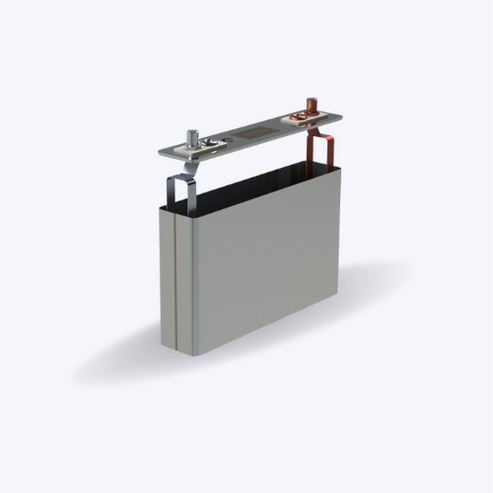

Lid Assembly

Manufacturing Components for Prototype Testing of Battery Cells

Quality Assurance

JIS Q 9100 Certified

Our Shimamoto Factory was certified in September 2015 for JIS Q 9100. This means it meets the requirements for quality management systems in manufacturing specialized battery parts for civil aircraft and space applications.

Production & Quality Control Systems

We take a centralized approach to production and quality control. From receiving an order to delivering the product, every stage is managed through an integrated database. Our manufacturing records ensure that our products are all traceable.

We will help you choose the best product for your needs.

Available in both English and Japanese.

Our professional staff will provide you with detailed customer service.