Aircraft Application

Specialized Processing for Aircraft Application

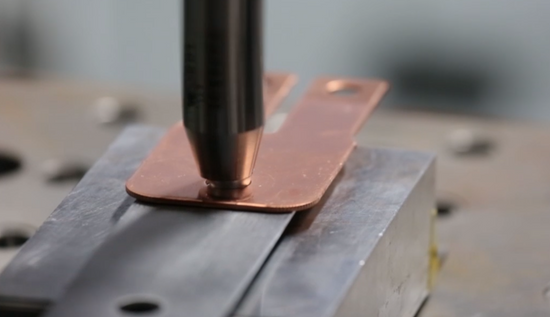

We have extensive experience in specialized processes, such as welding of thin films for safety valves, which rupture when the pressure in an airtight container increases, and lid assembly by riveting.

One-stop Components Production

In the manufacture of aircraft battery parts, special process control regulations are applied to many processes. There are also FAI and traceability management requirements.

This is a very labor-intensive process for ordinary manufacturers. We can handle such requirements as a manufacturer of specialized battery components under strict quality control.

Our customers can rest assured that they can place their orders with us, saving time and costs associated with vendor management.

We will help you choose the best manufacturing process for your needs.

Available in both English and Japanese.

Our professional staff will provide you with detailed customer service.